ANIMATION

Electromagnetic Removal

Full Screen Option Available

ABOUT

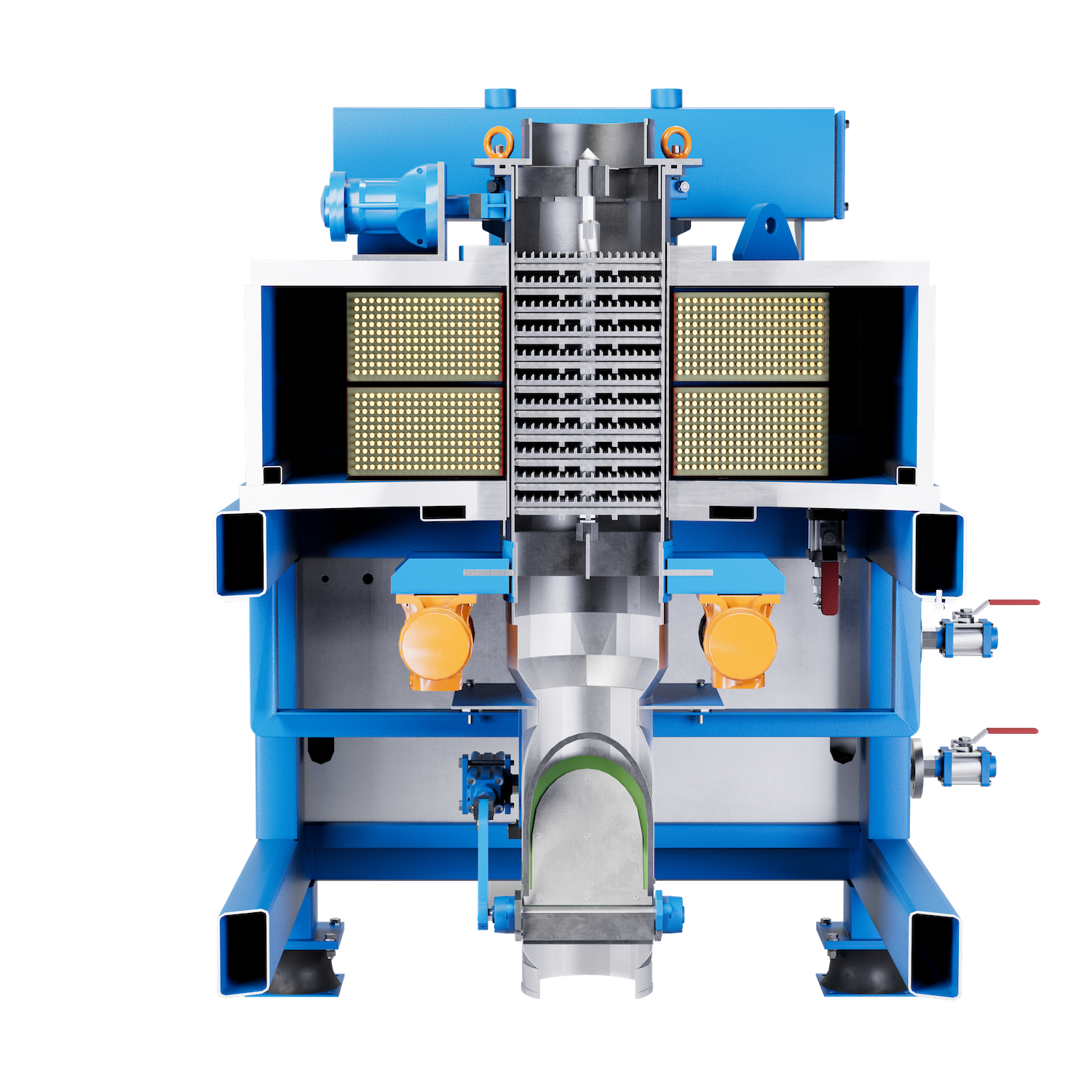

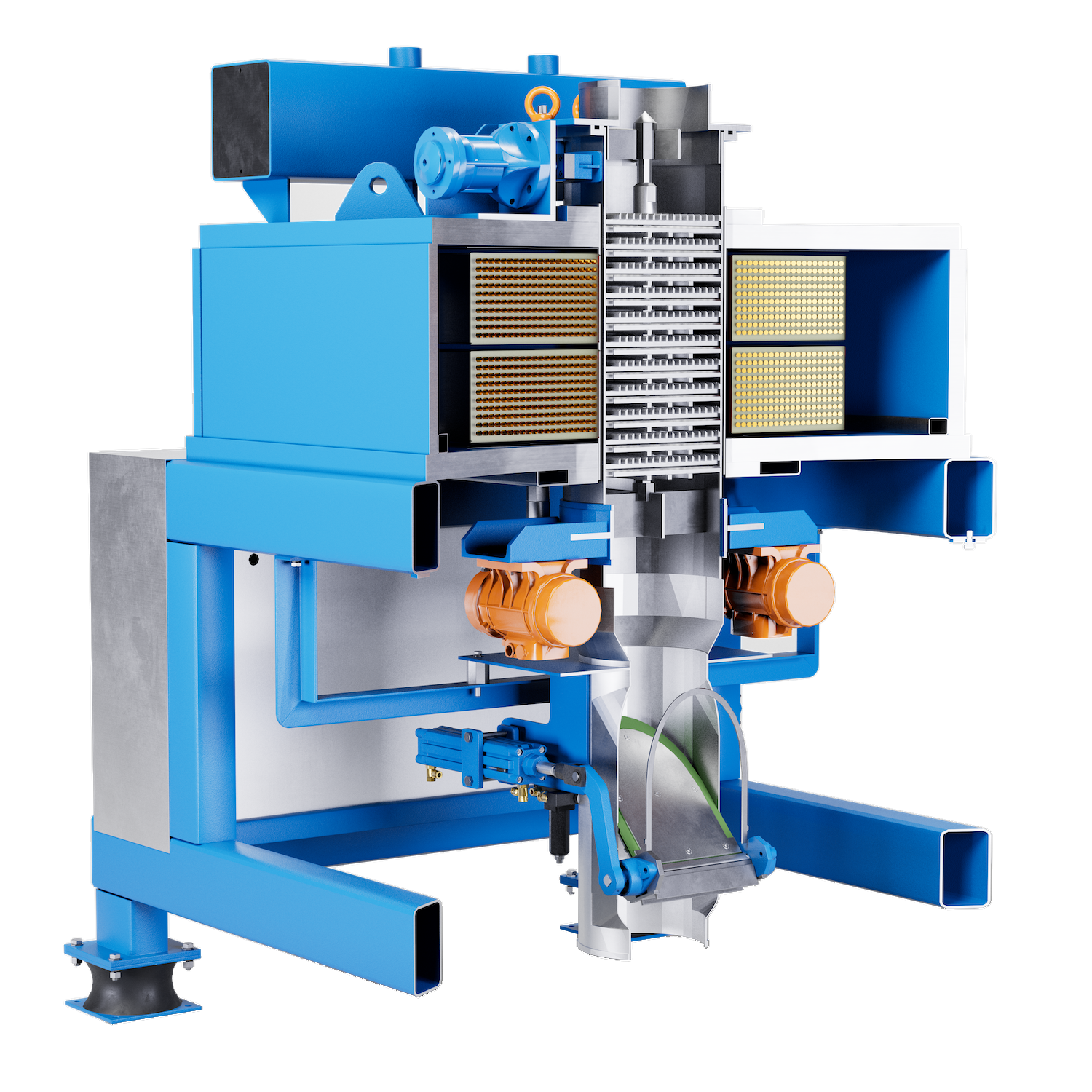

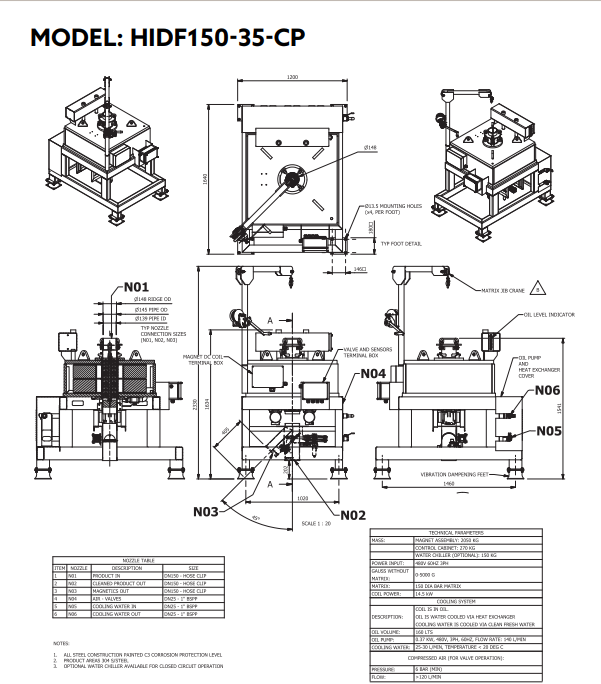

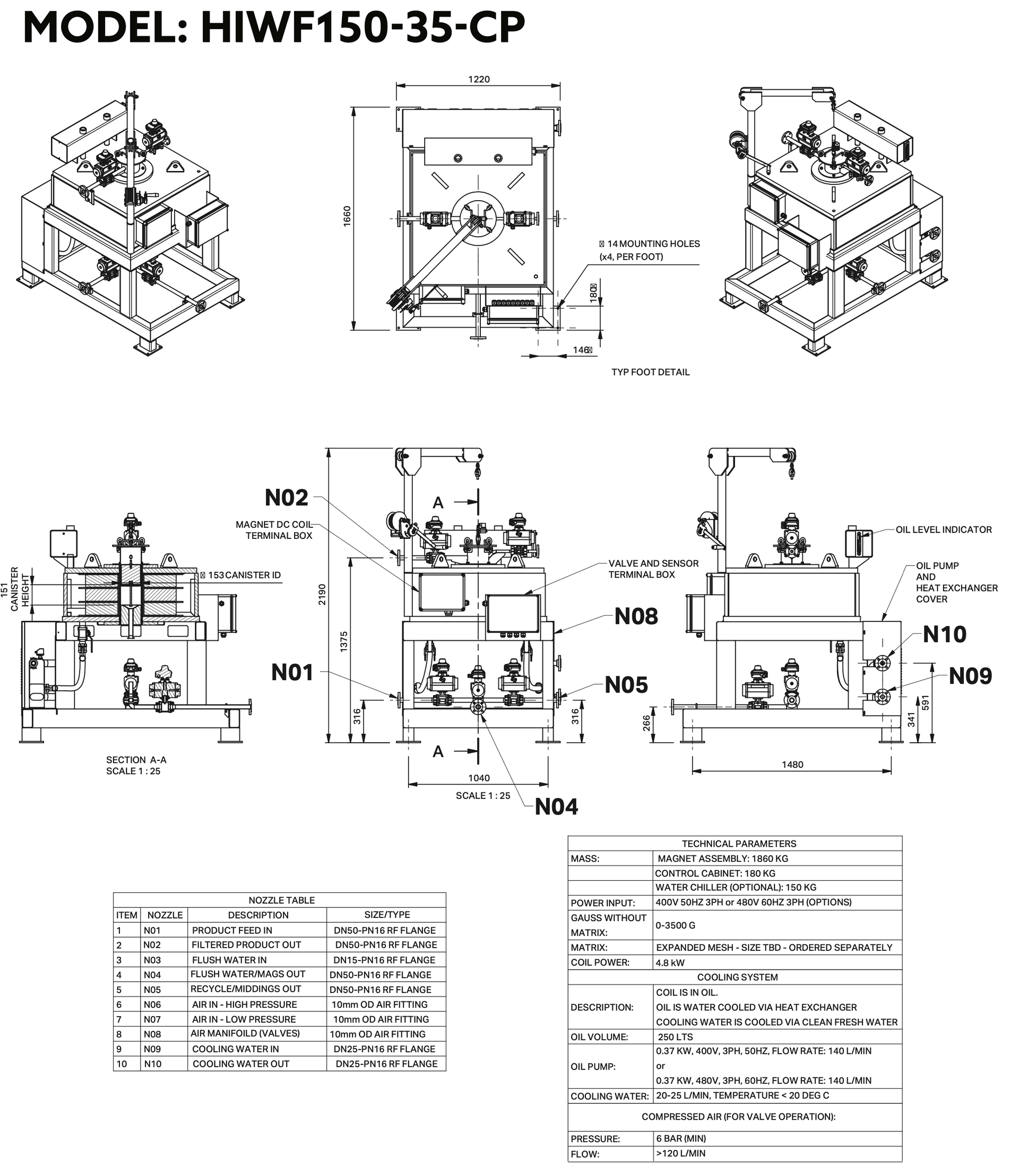

Bunting's High-Intensity Dry Electromagnetic Filter represents the cutting edge in magnetic separation technology for dry fine powders. Designed to meet the demanding needs of the recycling, battery manufacturing, and mineral processing industries, this advanced system offers unparalleled performance in removing fine iron and paramagnetic minerals from dry materials.

Key Features

- Powerful Magnetic Field: Generates a high-intensity magnetic field ranging from 3,500 to 5,000 Gauss, ensuring superior separation capabilities.

- Versatile Application: Ideal for industries dealing with dry fine powders, including recycling, battery manufacturing, and mineral processing.

- Multiple Models: Available in four sizes to accommodate various capacity needs, ranging from 0.15 to 0.60 m³/hr.

- Automated Operation: Fully automated using a Siemens S7-1200 PLC and HMI control system for precise and efficient operation.

- Energy-Efficient Design: Utilizes computer-optimized coils and an air-over-oil heat exchange system for optimal energy efficiency.

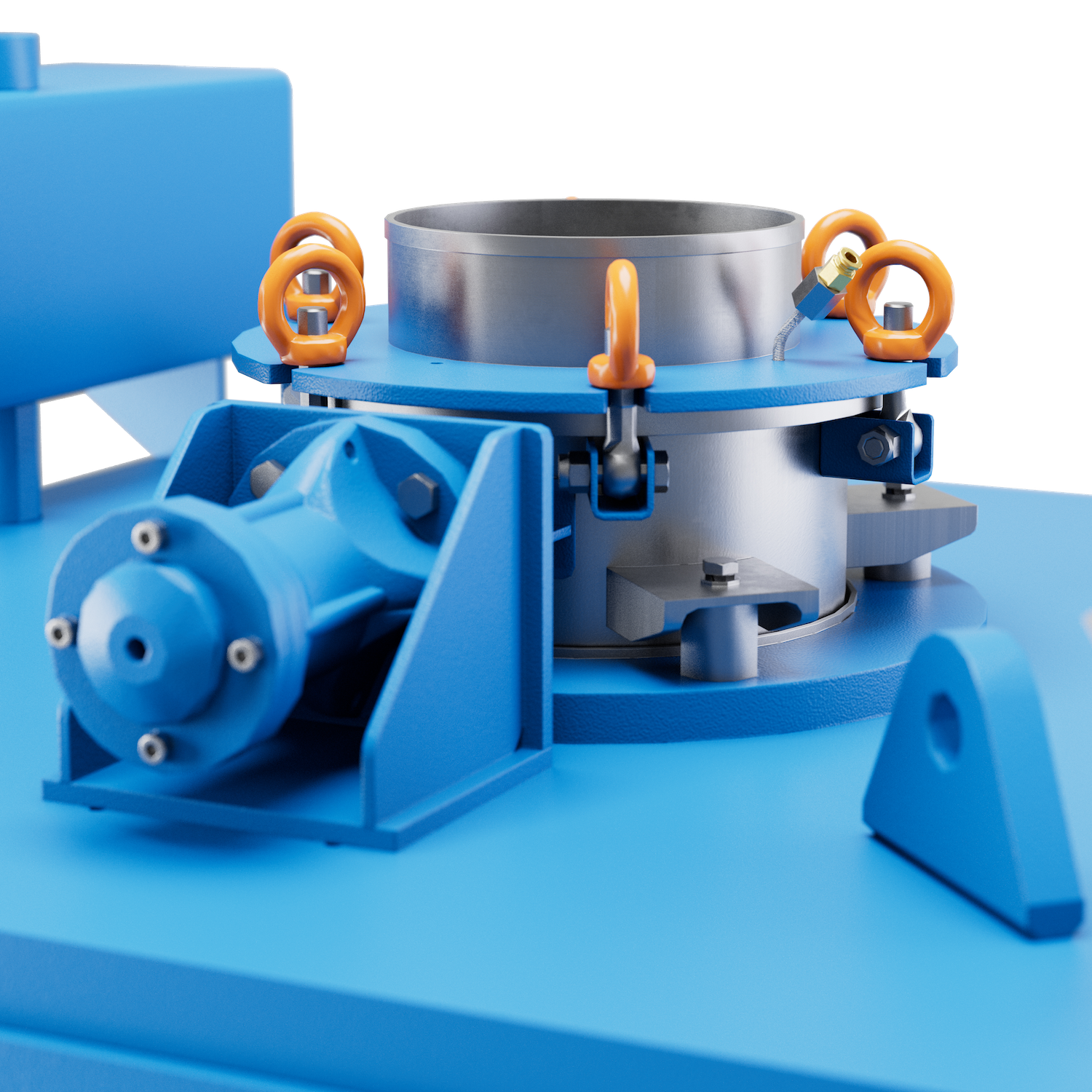

- Easy Maintenance: Features a removable jib crane for quick access to the matrix assembly, minimizing downtime.

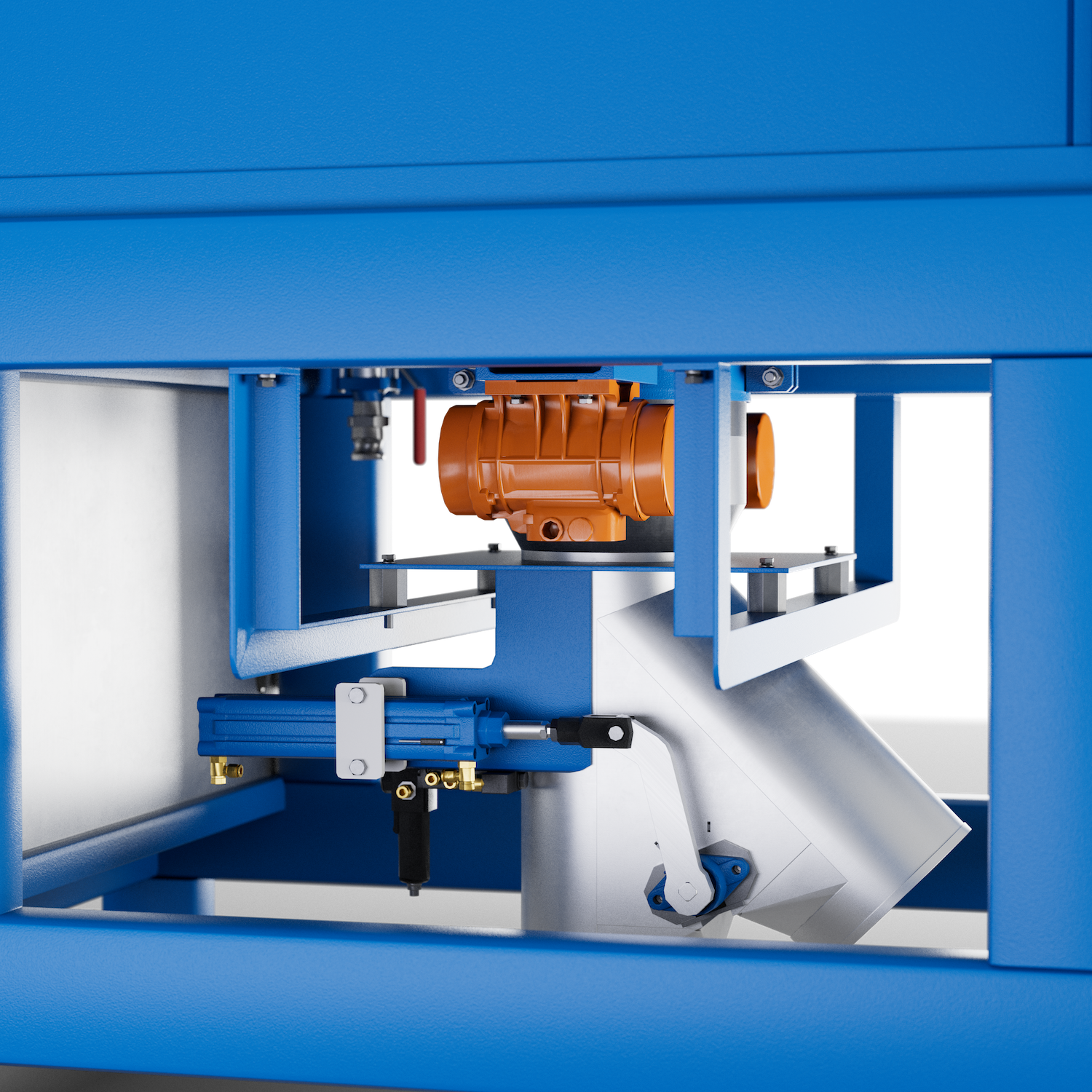

- Customizable Configuration: Incorporates a flap-style diverter valve that can be configured to suit various applications.

Technical Specifications

- Magnet Type: Electromagnet

- Magnetic Strength: 3,500 & 5,000 Gauss (background field)

- Material Processed: Dry Fine Powders

- Separation Capability: Fine Iron, Paramagnetic Minerals

- Control System: Siemens S7-1200 PLC (options available)

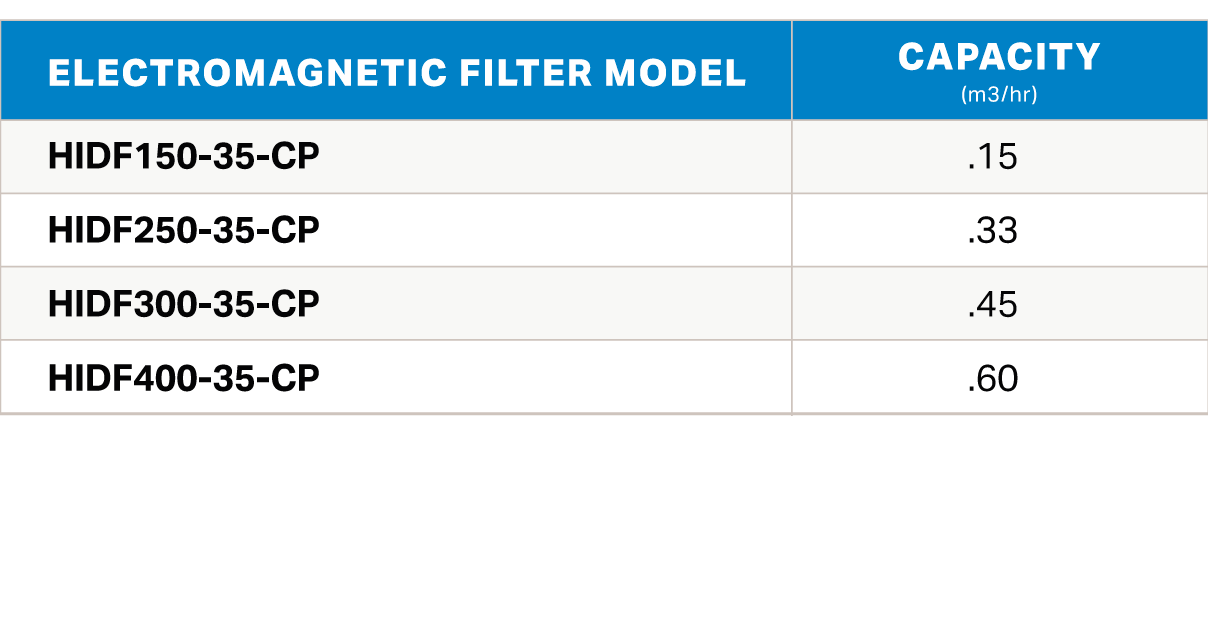

Models and Capacities

- HIDF150-35-CP: 0.15 m³/hr

- HIDF250-35-CP: 0.33 m³/hr

- HIDF300-35-CP: 0.45 m³/hr

- HIDF400-35-CP: 0.60 m³/hr

Advanced Features

- Automated Cleaning: Features an automated vibration cleaning cycle with adjustable parameters via the HMI interface, ensuring consistent performance.

- High Separation Efficiency: Achieves higher separation efficiency than permanent magnetic separators due to its significant background magnetic field strength and high magnetic field gradient on the matrix surface.

- Flexible Power Options: Available with power input options of 400V 50Hz 3PH or 480V 60Hz 3PH to suit global power standards.

- Robust Construction: All-steel construction with C3 corrosion protection level paint, ensuring durability in industrial environments.

- Stainless Steel Product Areas: Critical product contact areas are constructed from 304 stainless steel for cleanliness and longevity.

Cooling System

- Coil immersed in oil for optimal heat dissipation

- Oil cooled via a water-based heat exchanger

- Cooling water system uses clean fresh water

- Optional water chiller available for closed-circuit operation

Installation and Integration

The High-Intensity Dry Electromagnetic Filter is designed for seamless integration into existing production lines. Its compact design and flexible configuration options make it suitable for a wide range of industrial setups.

Testing and Optimization

Bunting offers controlled tests on laboratory-sized filters to confirm separation capabilities and optimize performance for each customer's specific application. This ensures that each installation is tailored to meet the unique requirements of your process.

Applications

- Recycling industry: Removal of fine magnetic contaminants from recycled materials

- Battery manufacturing: Purification of battery materials and removal of magnetic impurities

- Mineral processing: Separation of valuable paramagnetic minerals from non-magnetic gangue

Why Choose Bunting's High-Intensity Dry Electromagnetic Filter?

- Industry-leading magnetic field strength for superior separation

- Versatile design suitable for various dry powder applications

- Energy-efficient operation with advanced cooling system

- Easy maintenance and cleaning features to minimize downtime

- Fully automated operation for consistent, high-quality results

- Backed by Bunting's 60+ years of expertise in magnetic separation technology

Experience the next level of dry magnetic separation with Bunting's High-Intensity Dry Electromagnetic Filter. Contact our team of experts today to discuss how this advanced system can optimize your production process and improve product quality.